Enzyme Catalysis Platform Opens Magic Magic: Building a "Green Engine" for Chemical Reactions"

2020-01-17

When the first dawn of life wakes up from the hundreds of millions of years of evolution on the earth, enzyme-catalyzed reactions accompany life. Enzymes are widely present in various cells, and thousands of metabolic chemical reactions in organisms are completed under the action of enzyme catalysis. It can be said that every individual of life is like a wonderful chemical plant, with efficient and specific complex chemical reactions taking place all the time, and enzymes are the biocatalysts that promote these magical reactions. Chemists find inspiration in the mysterious organism: whether the "enzyme" that exists in life and has a magical effect can be used.

WuXi AppTec/Reports

When the first rays of life awaken from the billions of years of evolution on Earth, enzyme-catalyzed reactions accompany life. Enzymes are widely present in various cells, and thousands of metabolic chemical reactions in organisms are completed under the action of enzyme catalysis. It can be said that every individual of life is like a wonderful chemical plant, with efficient and specific complex chemical reactions taking place all the time, and enzymes are the biocatalysts that promote these magical reactions.

Chemists find inspiration in the mystery of living organisms: can the magical "enzymes" that exist in the body of life be used in chemical synthesis? For more than a century, the mysterious and wonderful "enzymes" have come from behind the scenes and become the object of study by many scientists. Just last year, enzyme molecular directed evolution technology scholars also won the Nobel Prize in chemistry.

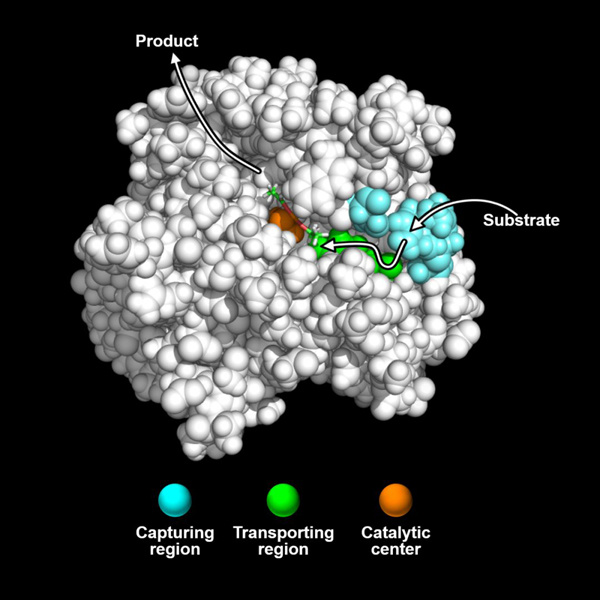

Enzyme-substrate transition state complex structure model

Focus on building an enzyme catalysis platform to carry a "green engine" for chemical reactions"

Hequan Pharmaceuticals captured the huge potential of enzyme catalysis in chemical synthesis reactions more than ten years ago and began to use enzymes in process research and development.

"When early customers request us, they will specify that a certain reaction requires enzyme catalysis. What we have to do is to catalyze and amplify the enzyme in the laboratory in production," recalled Dr. Fu Xiaoyong, senior vice president of Hequan Pharmaceutical. "But we were thinking about a question at that time. If the enzyme was not used in the process package given to us by the customer, would we still be able to provide a solution? Can we select the most suitable enzyme for the project from the existing enzyme molecules in the market?"

Since 2013, Hequan Pharmaceutical has gradually established an enzyme catalysis research and development team, and in the production and research and development of more than 20 new drugs, it has realized the research and development of the core process of enzyme-based preparation of key chiral intermediates, effectively reducing the generation of pollution sources and achieving The goal of green environmental protection and sustainable development. Since then, Hequan Pharmaceuticals has become an early company in the CDMO industry to explore enzyme catalysis, and has equipped an efficient and environmentally friendly "green engine" for chemical reactions ".

It is true that enzymes play an important role in chemical synthesis reactions as efficient and clean catalysts, but enzymes are still very "delicate" and "picky" about the environment ". Any change in temperature, pH or environmental factors in chemical solvents will change the catalytic ability of the enzyme, which will reduce the catalytic ability and completely lose the catalytic ability. In addition, enzyme catalysis is specific: an enzyme can catalyze only one or a class of chemical reactions. Scientists have played an image analogy-a key to open a lock.

So such a "character" of the enzyme, how to choose to meet the ever-changing chemical synthesis reaction? "Looking for enzyme" has become an important step to promote the development of enzyme catalysis. But where to find the enzyme? What if you can't find it?

AI technology combined with high-throughput screening to improve the efficiency of enzyme directed evolution

In fact, the types of enzymes available on a global scale are very limited and cannot be compared with the scale of chemical reagents. Hequan Pharmaceuticals found that if you want to provide partners with efficient enzyme catalysis solutions, you must find specific enzymes that are highly matched with substrates and target products. In other words, in the future, if Hequan wants to go further in the field of enzyme catalysis, it must have the ability to "transform enzymes! Thus, the Hequan Pharmaceutical enzyme directed evolution platform came into being.

In 2018, Hequan Pharmaceutical's enzyme directed evolution platform took a solid first step. In an important project, a key chiral intermediate synthesis of the original needs to be completed through 5 steps, and the yield is only 40%. However, as the project advances to the late clinical stage (P2b/P3), there is an urgent need to improve efficiency and reduce costs. To this end, the enzyme catalysis team of Hequan Pharmaceutical first screened the existing enzyme library and constructed a biocatalytic route, replacing the original five-step reaction with only one step reaction, increasing the yield to 76% and reducing the cost by 1/3. However, the route still needs to use three enzymes, two coenzymes, and control the pH value of the solution at the same time, the operation is not simple enough, and the cost advantage is not obvious enough.

In order to solve this problem, the team used cutting-edge big data and artificial intelligence technology to predict a small number of structural regions that may have a significant impact on the catalytic activity of the enzyme through innovative computer modeling. On this basis, the high-throughput directed evolution of the enzyme was realized. The magic of computer modeling is that the structure of the enzyme can be predicted based on the amino acid sequence and the enzyme molecules that meet the expected activity can be selected. Researchers need to turn the interaction of enzymes with substrates from a chemical problem into a computable mathematical problem. Then, the potential mutants of the computer recommend were quickly screened by the bacteria picking robot. The team completed the enzyme evolution in only one month through two rounds of AI prediction and robot screening. The reaction can be completed with only one enzyme and one coenzyme, with a yield of 90% and a cost reduction of more than 70% compared with the earliest five-step chemical route. This work has been highly recognized by the partners, and it has also laid a high technical starting point for the next STA enzyme evolution business.

Today, Hequan Pharmaceutical has a well-equipped high-throughput enzyme evolution laboratory that integrates cutting-edge technologies in multiple disciplines such as structural biology, mathematical models, high-throughput screening, and computer drug design. Hequan's enzyme directed evolution technology can realize the natural evolution process of millions of years in a few months, and evolve and modify existing enzymes in a directional and selective manner.

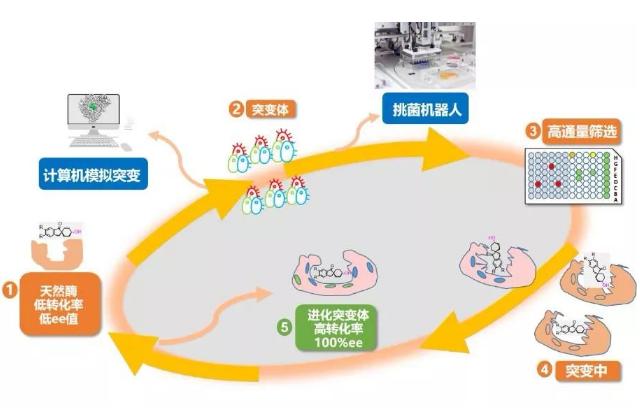

A picture to understand the high-throughput enzyme directed evolution technology of Hequan Pharmaceutical.

If the enzyme activity center is compared to a pocket, enzyme evolution is the process of pocket modification. When evolving with natural enzymes, the non-natural substrate often does not match the pocket, resulting in low reaction conversion and poor selectivity. At this time, the enzyme needs to be evolved and the pocket needs to be modified.

First, we design various pockets that may be suitable for the substrate through computational simulation. Then, through experiments to make these pockets, the so-called mutants. Then, thousands of mutants were put into 96-well plates by the bacteria picking robot, and then the substrate was added for high-throughput reaction, screening and analysis. Then find the mutant with high relative conversion rate and high selection. Through this round of screening, the matching degree of substrate and mutant pocket is greatly improved than that of natural enzyme, but it is not perfect, so it is necessary to continue to do the next round of computer design, experiment, screening and analysis with the optimized mutant. After several rounds of optimization, the matching degree of substrate and pocket will reach a relatively consistent degree, and the enzyme evolution is completed, and the enzyme with high conversion rate and high selectivity is obtained.

screening enzymes, evolving enzymes, mass production of enzymes

After years of development, the enzyme catalysis platform of Hequan Pharmaceutical has also experienced a process from passive enzyme selection in the early stage to active modification and evolution of enzymes. Enzymes that are fully evolved are new enzymes and cannot be used in process chemistry if they cannot be produced. Therefore, in the exploration of green chemistry, Hequan has never stopped here, but has continued to cultivate in the field of enzyme catalysis. Now Hequan Pharmaceutical has established an integrated capability platform for enzyme catalysis from screening to evolution and then to production in Jinshan Base in Shanghai. Not only to support their own demand for enzymes, but also to provide customers with professional enzyme production services.

Dr. Fu Xiaoyong said, "Hequan not only has the ability to screen and evolve enzymes, but also has the ability to mass produce enzymes, which can provide a full range of enzyme catalysis services for our partners. In the future, we will vigorously develop our own enzyme directed evolution database to provide more partners with high quality customized enzyme catalysis services."

At present, Hequan Pharmaceutical has more than thousands of batches of chemical reactions every year. It is expected that more and more reactions will use enzyme catalysis technology in the future, which will greatly reduce the cost of large-scale production and improve efficiency. From screening enzymes, to evolutionary enzymes, to mass production of enzymes, Hequan has equipped traditional chemical reactions with an efficient "green engine" and will lead green chemistry to a new future!

Related News